About Us

Dekeer Knives leverages decades of knife-making expertise to meet the cutting tool needs of clients across various industries. The company specializes in manufacturing doctor blades (ink scraper blades), circular blades, tungsten steel blades, serrated knives, and various custom-shaped blades.

Operating two dedicated factory bases—a Doctor Blade Factory and a Circular Blade Factory—Dekeer Knives boasts strong technical expertise, advanced production equipment, and sophisticated inspection facilities, ensuring a 100% pass rate for all products before shipment. The company’s doctor blades for the gravure printing industry are well-received by customers both domestically and internationally! Dekeer Knives offers an extensive selection of products, comprehensive specifications, ample inventory, and guarantees superior materials and precision craftsmanship. Dekeer Knives: Heart in Every Blade.

Need help? Contact me

Our Workshops

Provide customization services

CNC Machine Tools Workshop

We have an advanced CNC machine tool workshop to ensure the processing accuracy of our products.

Precision Finishing Workshop

Equipped with high-precision grinders and lifting equipment (for material handling), it enables efficient, accurate processing of blade workpieces. The standardized layout and bulk workpiece inventory ensure both machining precision and fast order fulfillment.

Precision Lapping & Polishing Workshop

Our Precision Lapping Workshop features high-spec surface lapping machines for precise grinding/polishing of blades and metal parts. With a professional lapping fluid system and stable speed control, it ensures workpiece flatness and smoothness, boosting final product quality.

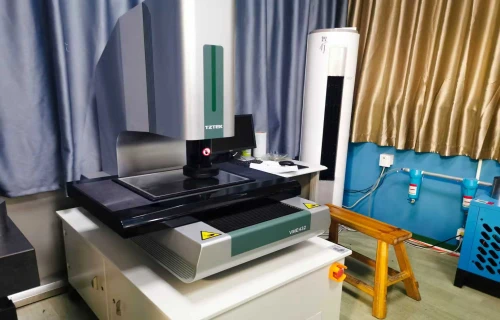

Inspection Workshop

By adopting 3D coordinate measurement technology, our inspection team can detect even the smallest deviations during production. This ensures that every product maintains consistent quality, durability, and cutting performance. Our CMM inspection process not only strengthens product reliability but also helps customers reduce downtime and improve operational efficiency.

Why Choose Us

Reason For Choosing Us

Direct Manufacturer

We operate as a direct manufacturer, ensuring stable quality control, competitive production costs, and consistent supply.

OEM Customization

Blade size, thickness, material grade and hole patterns can be customized to meet specific machine requirements.

Technical Support

Our experienced technical team provides fast pre-sales consultation and reliable after-sales support for industrial applications.