Blade Edge Shapes

| Lamella Blade Edge | Bevel Blade Edge |

Key attributes

| core components | blade | warranty | 3 months |

| brand name | dekeer | place of origin | Anhui, China |

| type | Doctor Blade | Product name | LL Doctor Blade |

| Application | Gravure printing, Flexo printing, Roller Coating, Adhesive coating | Material | Carbon Steel |

| Ink Types | Water based ink, UV ink, Corrosive inks with high pH and Ink containing fine metal particles |

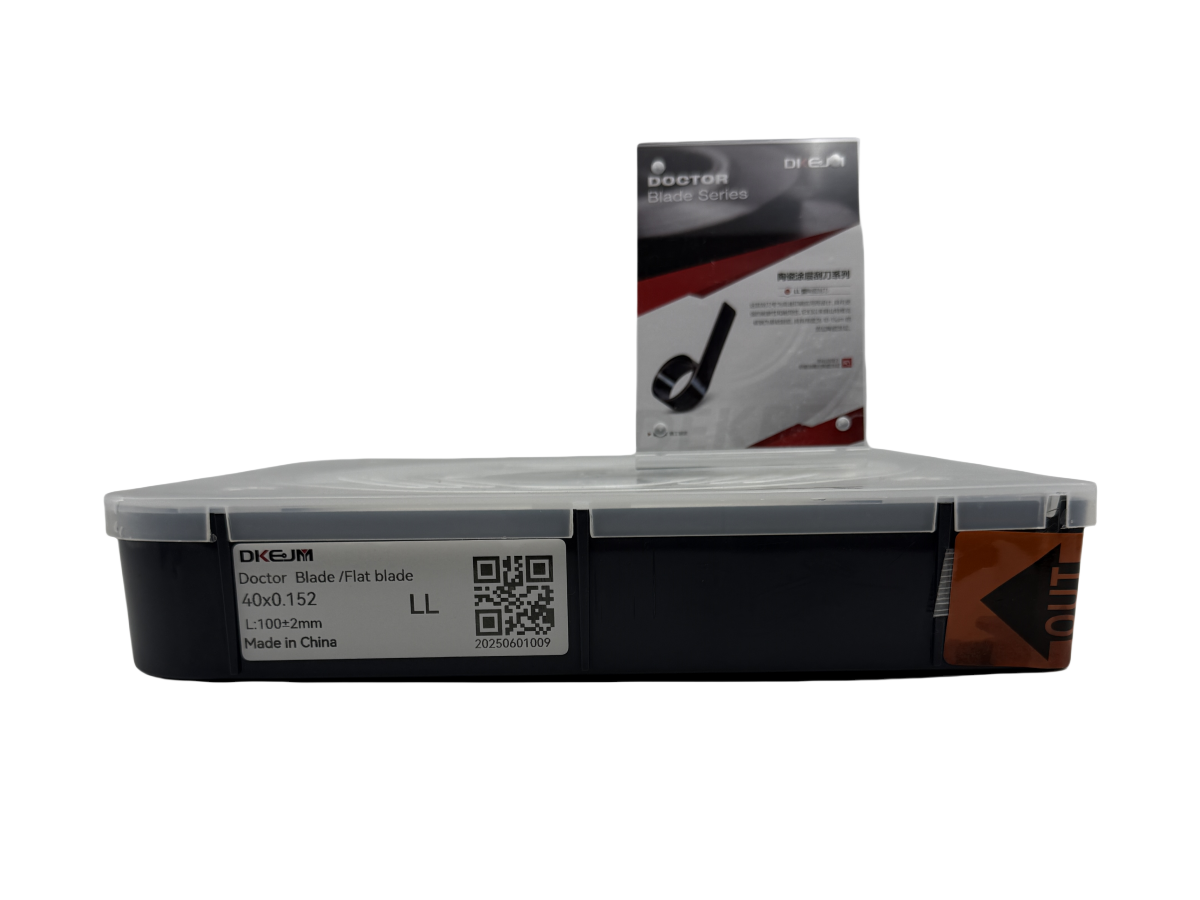

Packaging and delivery

| Selling Units | Single item | Single package size | 25X25X30 cm |

| Single gross weight | 10.000 KG |

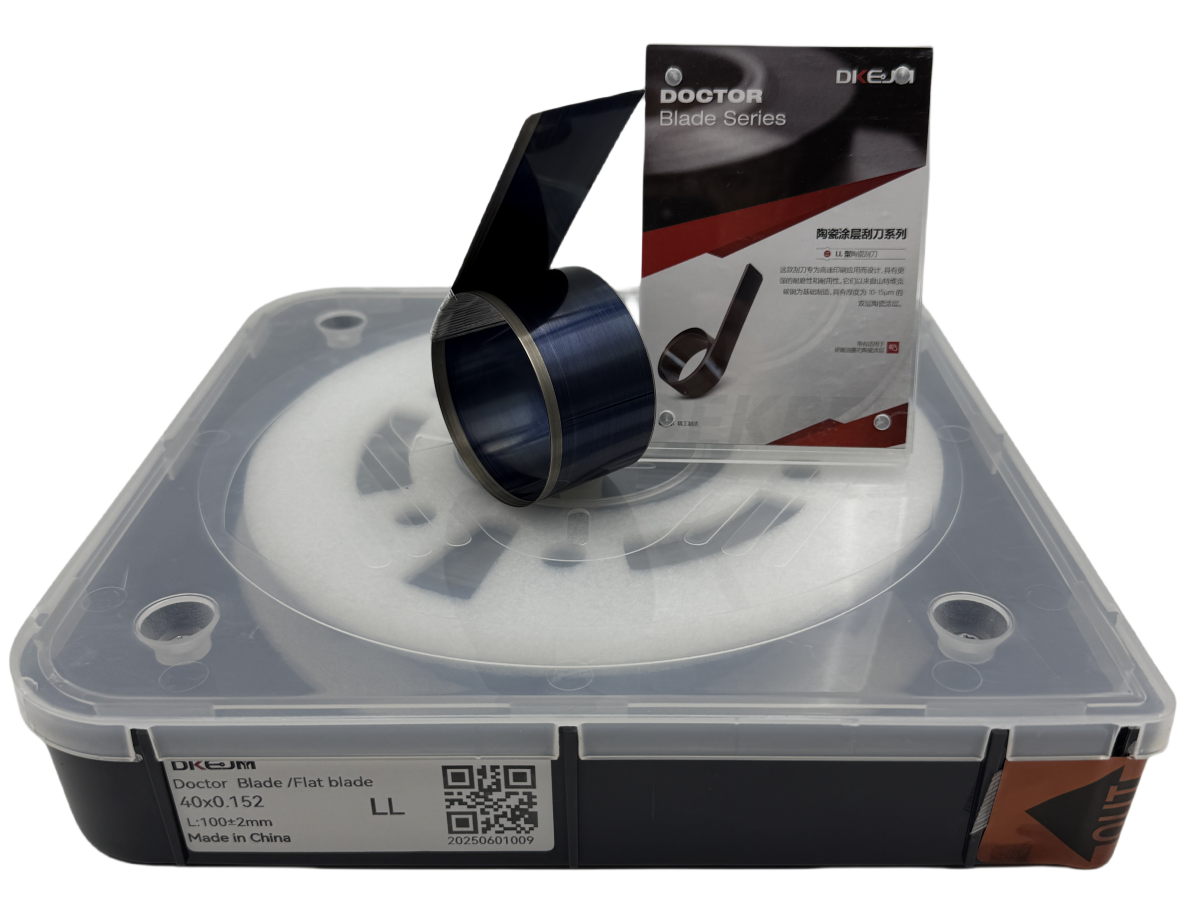

In the modern printing and coating industry, ceramic-coated doctor blades have become an essential solution for achieving high-quality and consistent results. With advanced doctor blade

coating technology, these blades are designed to deliver superior wear resistance, precise ink metering, and extended service life, making them ideal for high-speed and demanding production environments.

What Are Ceramic-Coated Doctor Blades?

Ceramic-coated doctor blades are manufactured by applying a protective ceramic layer to the blade surface. This coating reduces friction, minimizes abrasion, and ensures longer durability

compared to conventional steel blades. As a result, they provide stable and clean wiping performance across various printing and coating applications.

Discover more about DKE Blade’s ceramic-coated series.

Key Benefits of Ceramic-Coated Doctor Blades

Extended Service Life – The ceramic coating significantly increases durability, reducing the need for frequent blade replacement.

Superior Abrasion Resistance – Especially effective when working with metallic inks, solvent-based coatings, or abrasive materials.

Consistent Print Quality – Guarantees accurate ink transfer and defect-free printing with stable doctoring.

Reduced Downtime and Costs – Longer blade life and less maintenance lead to higher production efficiency.

For more technical insights, visit Provident Blades’ analysis on ceramic-coated doctor blades.

Applications Across Industries

High-speed printing: Flexographic and gravure printing for packaging and labels.

Coating processes: Wide-web coating, varnishing, and surface finishing.

Electronics and energy materials: Precision coating for films, foils, and battery electrodes.

Explore additional products such as round cutting blade to complement your production needs.

Conclusion

By combining durability, accuracy, and efficiency, ceramic-coated doctor blades provide a reliable solution for industries requiring high performance and cost-effective operation. Investing in advanced doctor blade coating technology ensures stable production, consistent quality, and long-term savings.

Learn more about DKE Blade’s full range of doctor blades to find the right product for your application.