Key attributes

| core components | blade | warranty | 3 months |

| brand name | dekeer | place of origin | Anhui, China |

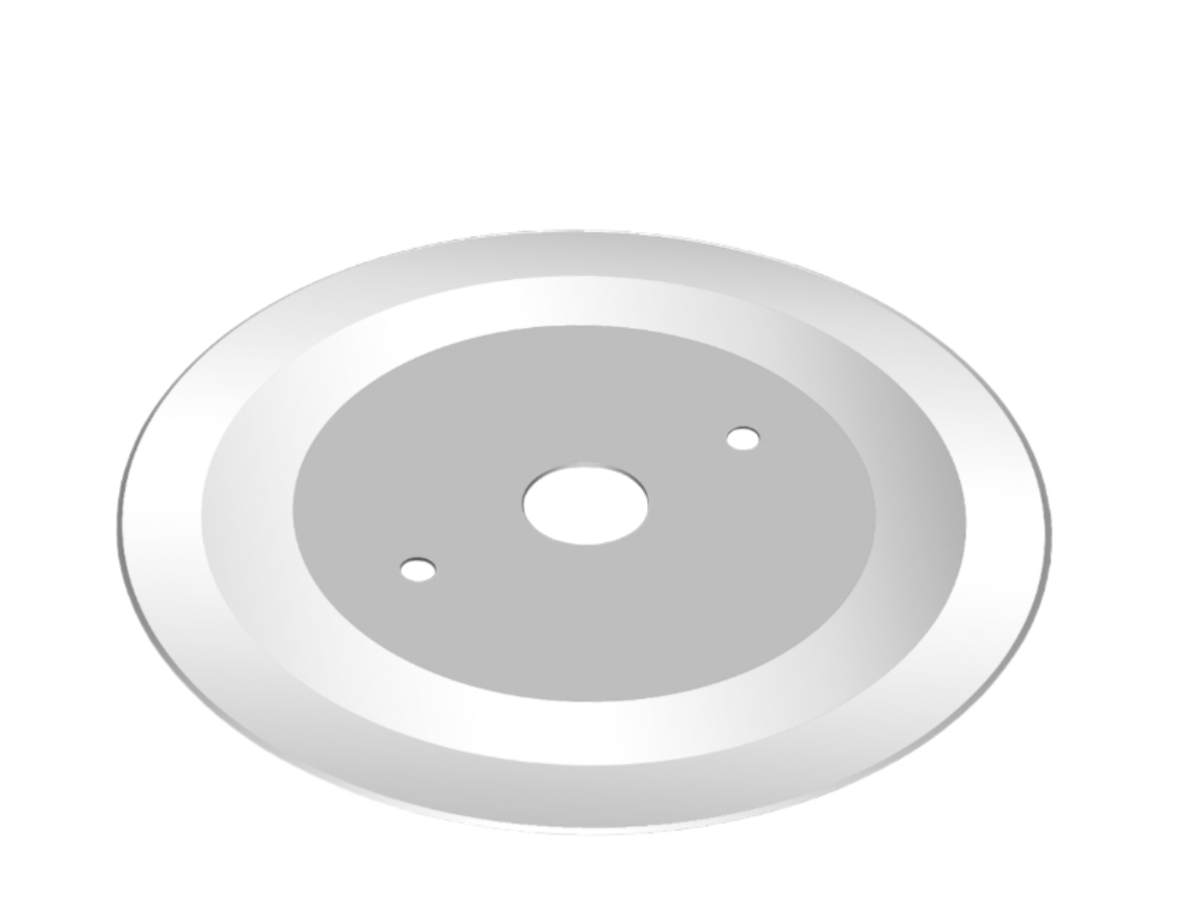

| type | Round Blade | Product name | Disc Slitting Circular Knife |

| Usage | Cutting films, paper, fabrics, and other materials | Material | K5/D1/SKD11/D2/SKH-9/SKH-51 |

| Hardness | HRC:59°-61° | Supply type | Make-to-order |

Packaging and delivery

| Selling Units | Single item | Single package size | 25X25X30 cm |

| Single gross weight | 10.000 KG |

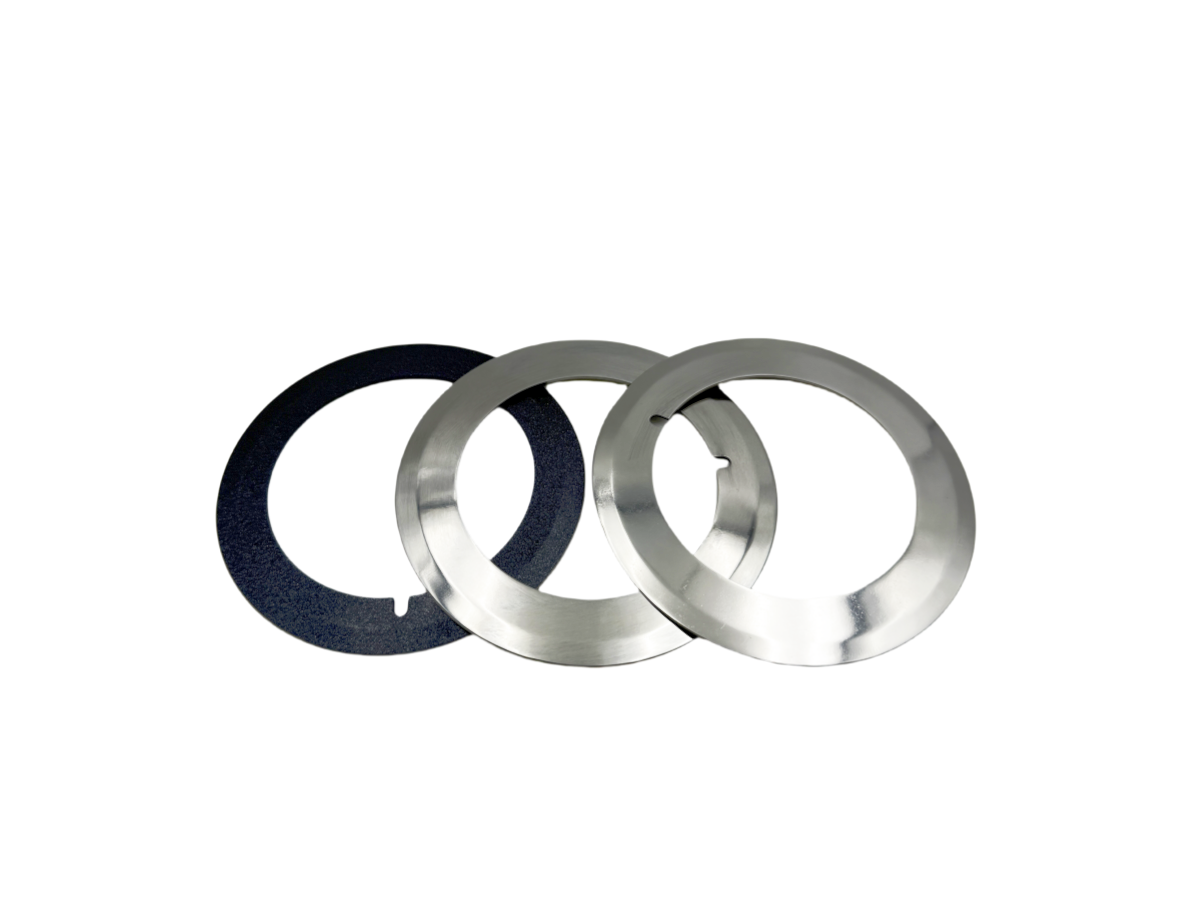

In industries such as film production, packaging, printing, and textiles, the performance of cutting tools is measured not only by sharpness but also by hardness, wear resistance, and dimensional accuracy. Dekeer’s Disc Slitting Circular Knife is manufactured with advanced heat treatment and premium-grade steels, ensuring consistent cutting performance, reduced downtime, and extended tool life in high-speed production lines.

1. Technical Specifications and Performance Advantages

Material Options for Different Applications

SKD11 / D2 Tool Steel: Excellent wear resistance and hardness stability for continuous mass production.

SKH-9 / SKH-51 High-Speed Steel: Maintains sharpness under high temperature and high-speed conditions.

K5 / D1 Steels: Balanced toughness and cutting edge sharpness, suitable for multiple industrial uses.

Hardness Range: HRC 59°–61°

Precisely controlled through advanced heat treatment technology, ensuring tool durability and stable cutting quality.Available Sizes and Customization

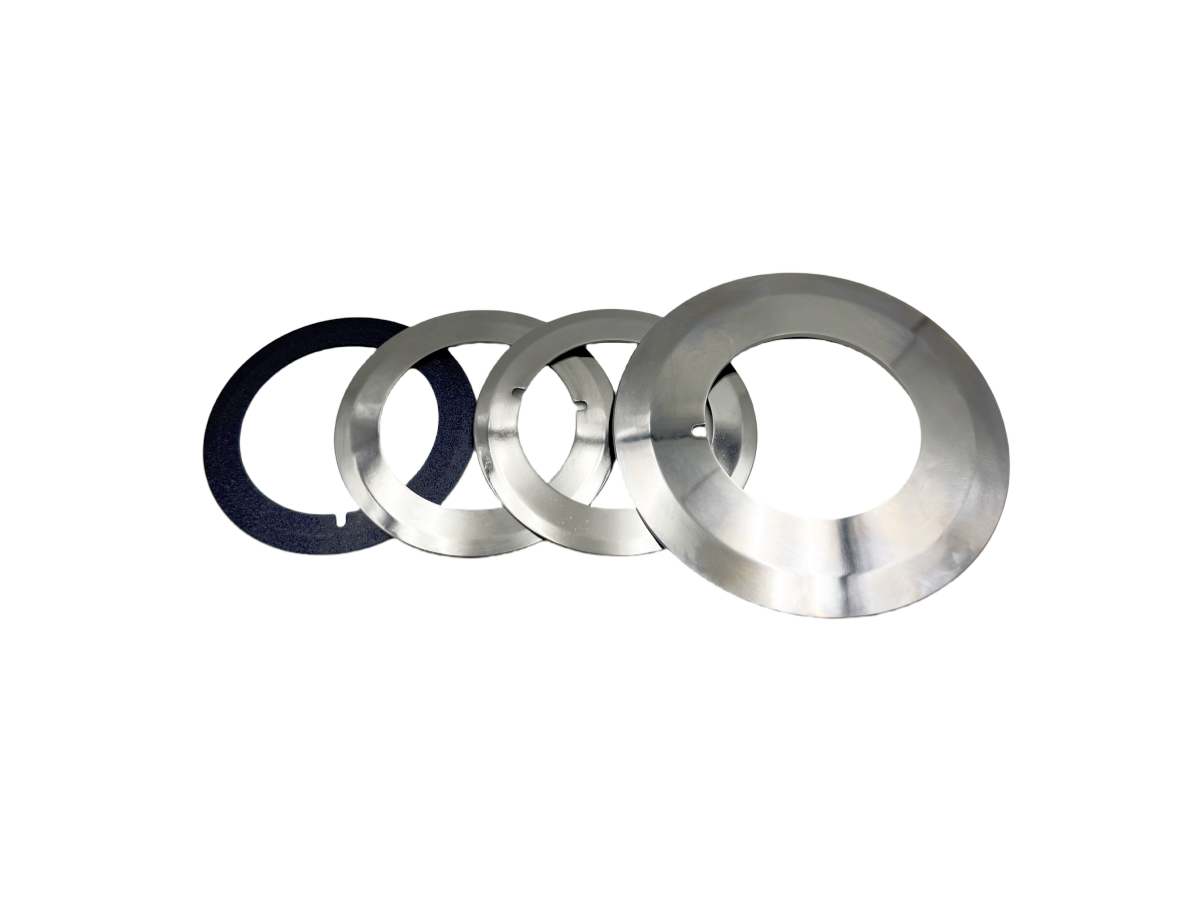

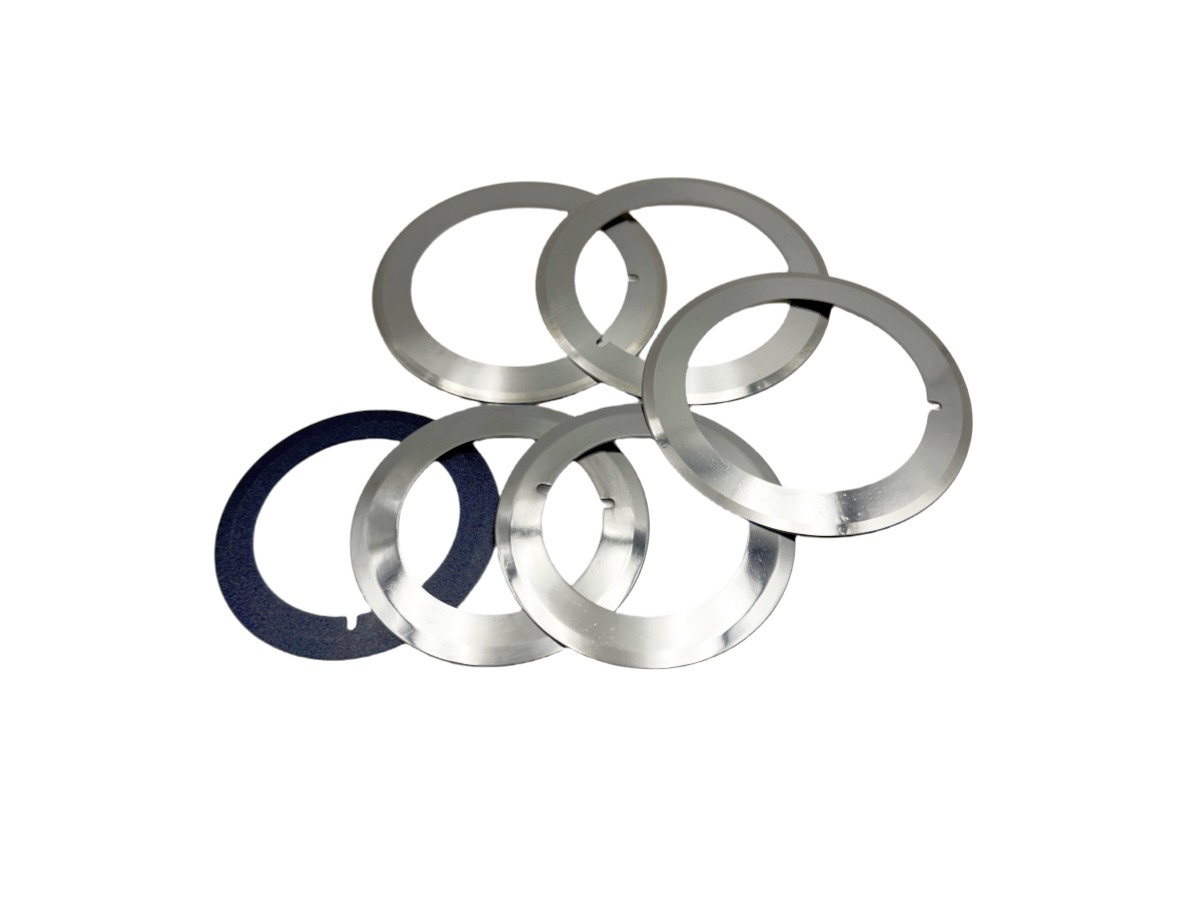

Standard dimensions include Φ68×40×1.0 mm, Φ68×46×1.0 mm, Φ100×70×1.2 mm, with full OEM/ODM customization support.

👉 View more circular knife specifications

2. Application Materials and Cutting Compatibility

The Disc Slitting Circular Knife can cut a wide variety of materials, such as:

Films & Plastics: PVC, PET, PE, PP, BOPP

Paper & Board: Coated paper, kraft paper, wallpaper

Adhesive Products: Medical tapes, double-sided tapes, protective films

Textiles & Nonwovens: Cotton fabric, synthetic cloth, nonwoven materials

Functional Materials: Rubber magnets, foams, label cloth

Each blade is manufactured under strict process control to ensure smooth cutting edges, minimal burrs, and consistent quality required by high-end packaging and printing industries.

(Reference: ISO Industrial Standards)

3. Quality Assurance and Packaging

Warranty Service: All Dekeer circular knives come with a 3-month warranty, ensuring reliable performance and after-sales support.

Packaging & Logistics: Each unit weighs around 10 kg, with packaging dimensions of 25×25×30 cm, making transportation and storage more efficient.

4. Industry Applications

Printing & Packaging: Precision cutting of films, labels, and coated papers.

New Energy Materials: Cutting photovoltaic backsheet films and lithium battery separator films.

Textile Industry: Accurate fabric and nonwoven cutting, reducing material waste.

Medical Materials: Cutting medical adhesive tapes and specialty films with clean edge quality.

👉 Related Product: Three-Hole Tungsten Carbide Blade,also widely used in film slitting and printing applications, perfectly complementing circular knives.

5. Why Choose Dekeer

Manufactured in Anhui, China – strong cost-performance advantage

Multiple steel grades & hardness options – adaptable to different industrial requirements

OEM/ODM support – quick customization and small-batch orders available

Technical consultation – dedicated support team for blade selection and process optimization

📌 Contact Dekeer today to request customized Disc Slitting Circular Knife solutions and enhance your cutting efficiency.