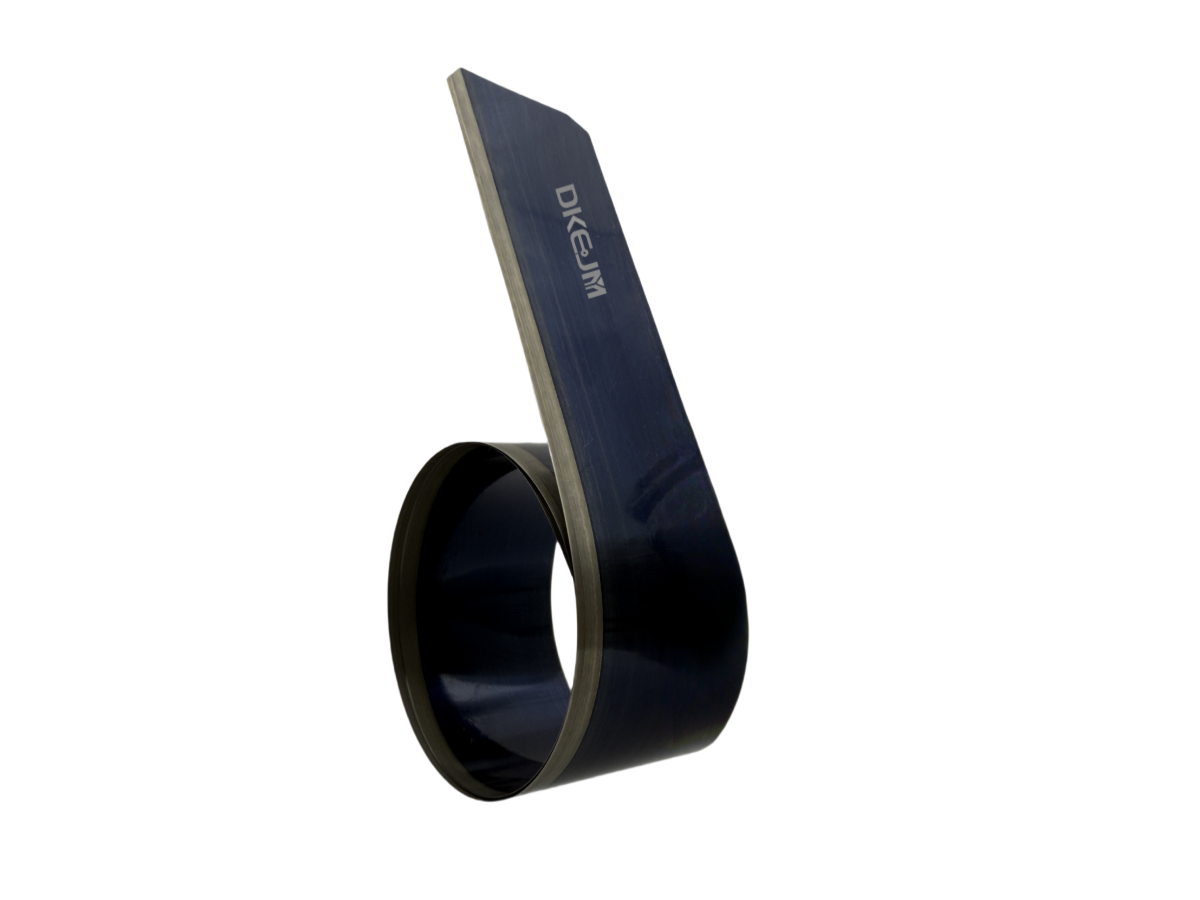

Blade Edge Shapes

| Lamella Blade Edge | Bevel Blade Edge |

Key attributes

| core components | blade | warranty | 3 months |

| brand name | dekeer | place of origin | Anhui, China |

| type | Doctor Blade | Product name | BC Doctor Blade |

| Application | Gravure printing, Flexo printing, Roller Coating, Adhesive coating | Material | Carbon Steel |

| Ink Types | Water based ink, UV ink, Corrosive inks with high pH and Ink containing fine metal particles |

Packaging and delivery

| Selling Units | Single item | Single package size | 25X25X30 cm |

| Single gross weight | 10.000 KG |

In gravure printing and flexographic printing, the doctor blade plays a crucial role in ensuring precise ink metering and high-quality results. Our coated doctor blades deliver superior performance and durability, making them the ideal choice for demanding printing applications.

Why Choose a Coated Doctor Blade?

Improved Print Quality

The coating reduces friction between the doctor blade and the cylinder or anilox roll, ensuring cleaner wiping and minimizing defects such as ink spitting and streaking.Longer Blade Life & Less Downtime

Coated blades provide enhanced wear and corrosion resistance, extending service life and reducing production downtime caused by frequent blade changes.Stable and Consistent Performance

The lubrication effect of the coating ensures smoother wear, resulting in consistent performance throughout long production runs.Specialized Coating Options

Advanced coatings such as ceramic further increase resistance to abrasiveness and maintain precision even under high-speed and high-pressure conditions.

👉 For bulk inquiries and sample requests, please visit our Alibaba Coated Doctor Blade Page.

Applications

Gravure Printing: Delivers precise ink transfer for packaging, decorative prints, and publications.

Flexographic Printing: Ensures clean wiping of the anilox roll for consistent ink transfer on labels, corrugated packaging, and films.

Coating Processes: Suitable for roller coating and adhesive applications requiring uniform coating.

Benefits for Printers

By using coated doctor blades, printers can achieve:

Higher print quality with fewer defects

Lower maintenance costs with reduced blade replacement

Versatile performance across multiple printing and coating environments

Conclusion

For printers seeking enhanced performance, durability, and cost efficiency, the coated doctor blade is a proven solution. With its advantages in wear resistance, print stability, and material compatibility, it is indispensable for gravure, flexographic, and coating applications.

👉 Compare more options: check our Carbon Steel Doctor Blade and Stainless Steel Doctor Blade for additional solutions.