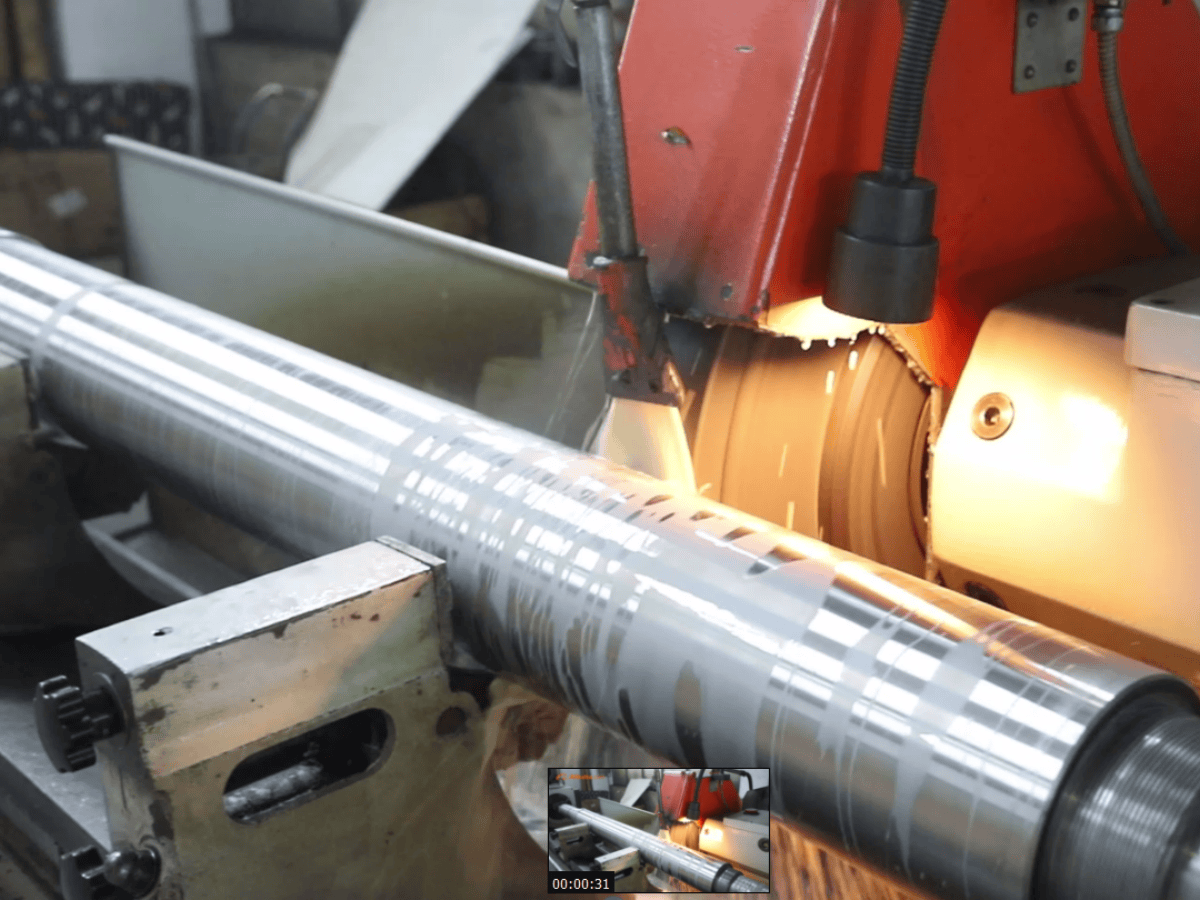

| Raw Material Storage Area We use high-quality imported raw materials to ensure the quality reliability of our manufactured products. |  | Blade Sharpening Workshop Precision machining of our ink doctor blades is performed within a standalone, purpose-built sharpening workshop, equipped with state-of-the-art CNC sharpening machinery. This guarantees cutting edges that achieve industry-leading precision standards. |

| Polishing Workshop Equipped for polishing treatments that improve blade sharpness, smoothness, and durability. |  | Finished Products Storage Area We maintain a dynamic inventory of over 3,000 boxes of ink doctor blades. Our stock covers the full spectrum of specifications—from narrow to wide-web presses—ensuring immediate availability of any blade model without lengthy delays. |

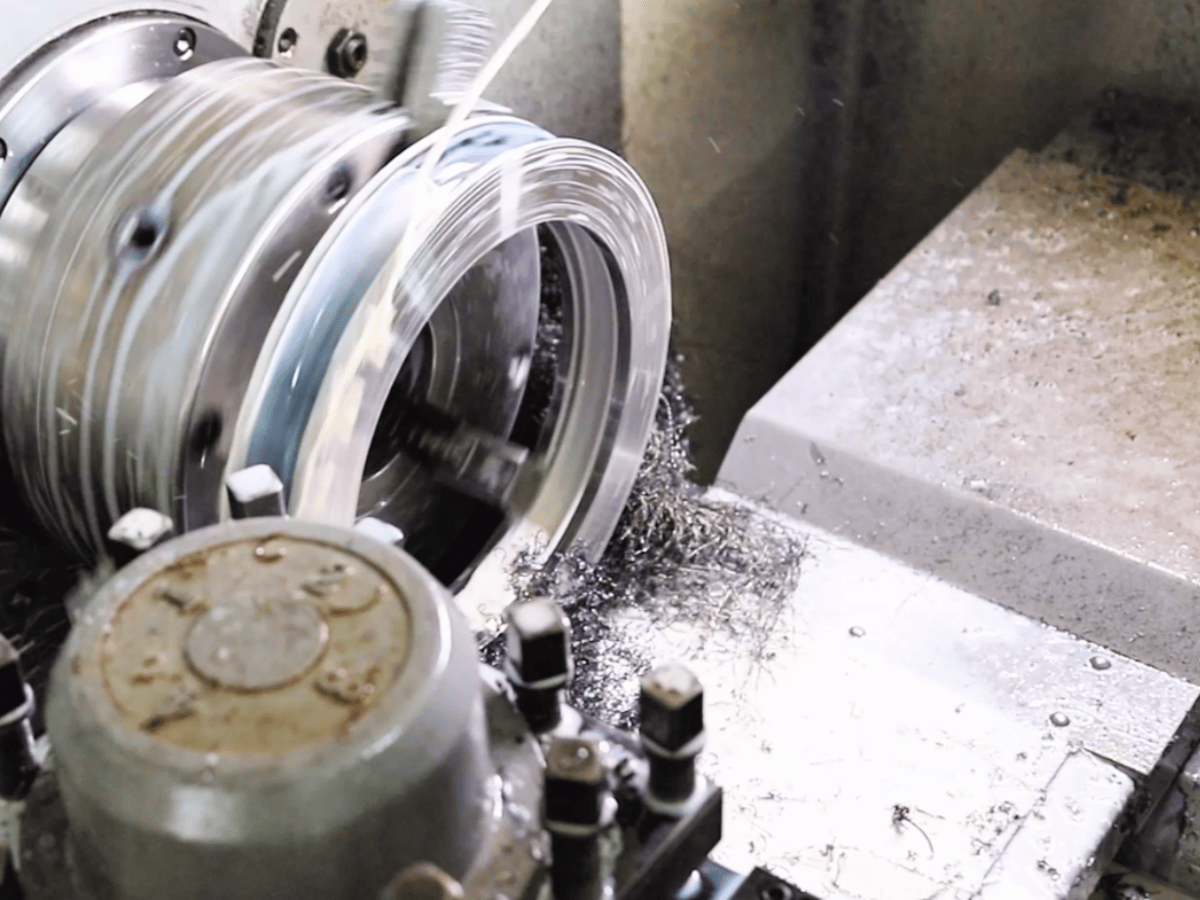

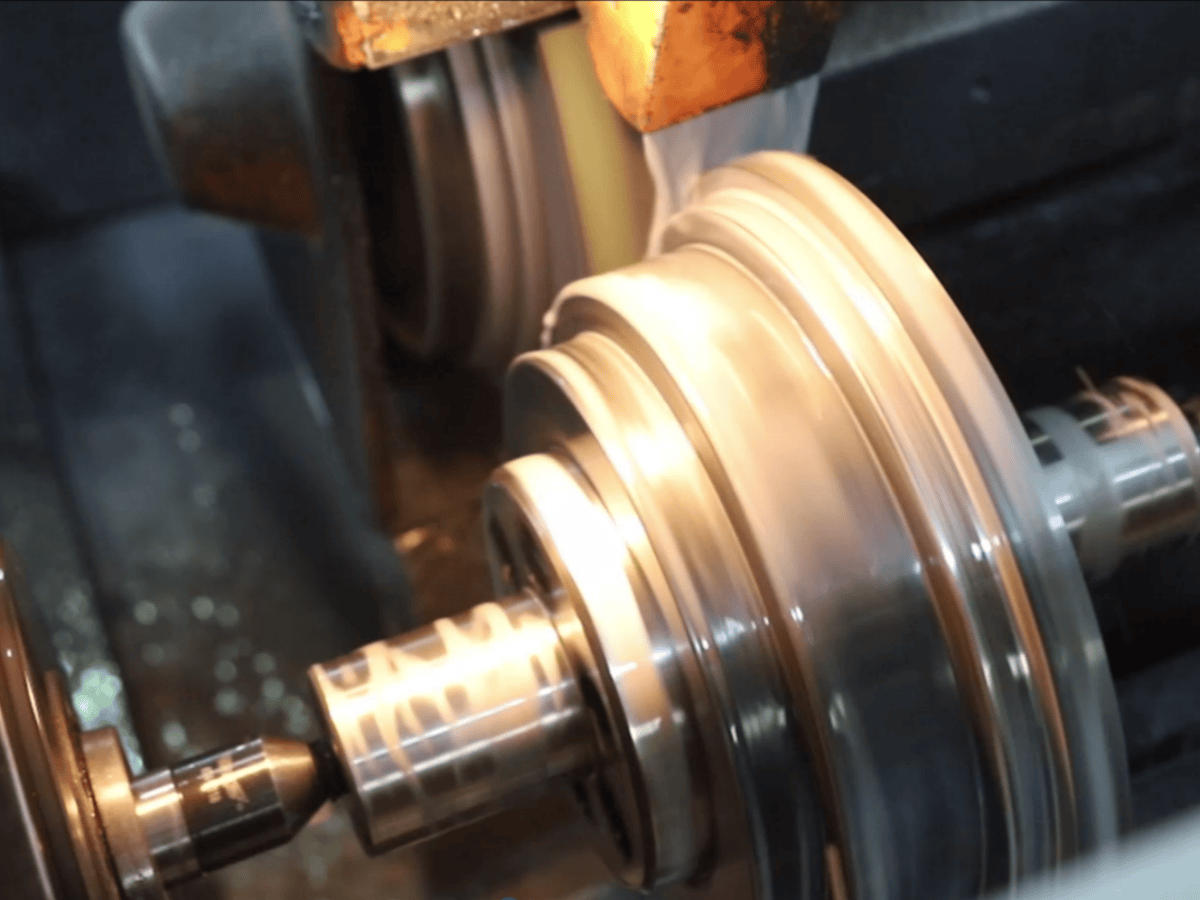

| CNC Machine Tools Workshop We have an advanced CNC machine tool workshop to ensure the processing accuracy of our products. |  | Inspection Workshop By adopting 3D coordinate measurement technology, our inspection team can detect even the smallest deviations during production. This ensures that every product maintains consistent quality, durability, and cutting performance. Our CMM inspection process not only strengthens product reliability but also helps customers reduce downtime and improve operational efficiency. |

|  |  |  |

English